Chemical Engineers spent years experimenting before they came up with the perfect chemicals for the job. They developed a family of refrigerant gases called hydroflourocarbon which had extremely low boiling points. These chemicals would boil at temperatures below 0 degrees Celcius at atmospheric pressure. So finally, we can begin to describe the mechanical refrigeration process called ‘Vapour Compression’.

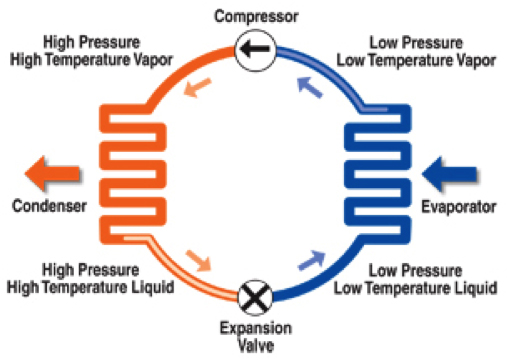

A Vapour Compression system has 4 main components. Compressor, Condenser, Expansion-device and Evaporator.

- Step 1: Beginning at the compressor, the refrigerant is compressed and leaves the compressor as a high-temperature, high-pressure gas.

- Step 2: The hot refrigerant enters the condenser, which is usually fan-forced air-cooled, then the refrigerant leaves the condenser as a warm liquid and continues on to the thermal expansion valve.

- Step 3: The expansion valve meters the proper amount of refrigerant into the evaporator.

- Step 4: There is a sudden pressure drop after the expansion valve converts the high-pressure warm liquid refrigerant into a low-pressure cold gas. The cold gas absorbs ambient heat from fan-forced air passing through the evaporator. This ambient heat converts the refrigerant into a cool, dry gas. From here the refrigerant reenters the compressor to be pressurized again, and the cycle repeats.